Cutting edge engineering and top class design are used in unique synergy in all our products. During the design process we focus on USABILITY,

ERGONOMICS and overall USER EXPERIENCE.

We just care about exceeding our customer's

needs !

In the Bangalore Research & Development center, the project teams get to work on the full product development lifecycle.

- Collaborate with the marketing team to understand business, product & user needs.

- Work on feasibility analysis inclusive of Concept generation & cost feasibility, perform risk analysis, and develop prototypes to prove concepts.

- Perform detailed Design & Development activities to complete the engineering of the complete product from prototype stage to final design which will be qualified against all relevant medical safety standards.

- Perform all necessary Testing/Verification & Validations.

- Work with regulatory teams for CE certification of the product.

- Collaborate with our production sites in Europe to transfer the design for serial production.

- Support the Product post launch.

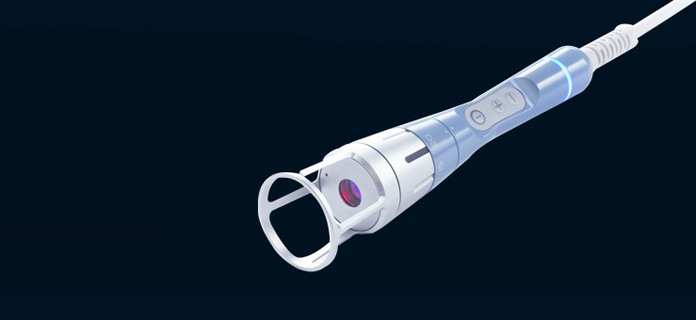

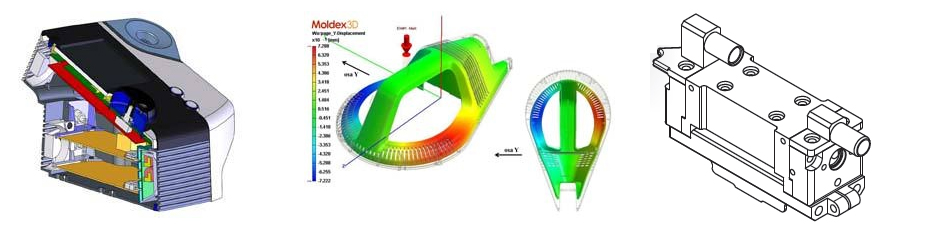

MECHANICAL DESIGN

Design of device's detailed mechanical structure and accessories involves project analysis, 3D modeling, selection of proper materials and production technologies, precise mechanical and optical parts construction, design of control elements. All mentioned are results of collaboration in product teams. Just for plastic parts we use machining, injection molding - classic; foam filled (TSG), RIM, vacuum molding, bending, plastics bonding, inking-pad printing and screen printing. Metal parts in our devices are produced by various types of machining, cutting (laser, water-jet, punching), extruding, bending, welding, soldering, electroplating (zinc-coating, nickel plating, …), powder coating, varnishing, dyeing, inking-pad printing, screen printing, …).

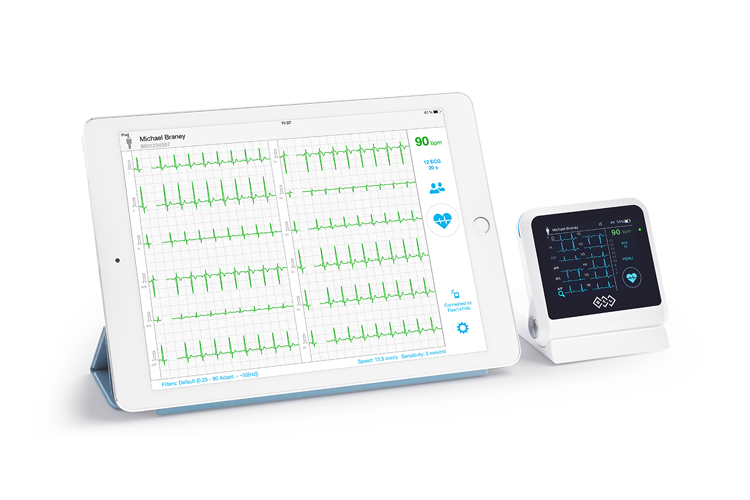

HARDWARE & SOFTWARE DESIGN

Throughout modern and state-of-the-art electrical components used in our designs we try to push forward frontiers of therapy accuracy and patient safety. Our designs fulfill severe requirements given by various medical and EMC standards. Our designs work from DC to gigahertz frequencies, from microvolts to kilovolts voltages and from miliwatts to kilowatts in power. Our teams design circuits with microcontrollers, A/D and D/A converters, low-noise analog input amplifiers, high-voltage output amplifiers, generators and amplifiers for RF signals. We develop low-level embedded firmware for our devices as well as application software for PC running in multiplatform environments. Our software controls actuators, measures physical entities, regulates, communicates through modern peripherals or processes and evaluates biological signals.

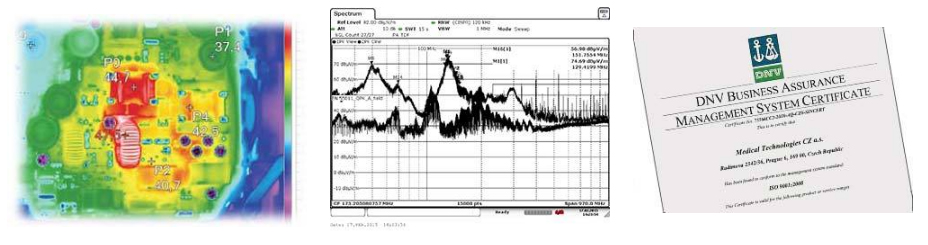

TESTING & CERTIFICATION

We apply verification processes based on product and quality requirements on designed prototypes as well as on our final products which are in pre-production phase. Assimilation of new technologies in device design often requires design of new test and measurement methods. For all our devices we perform full spectra of EMC tests, testing of climatic resistance, operational temperatures measurements and analysis, testing of safety properties and cable and connector testing. As software verification and validation is required for all our products out team prepares test scenarios based on software specification and provide all necessary tests. A majority of our tests are in accordance with standards internationally accepted for world-wide certifications (CB, CE, FDA etc.).